Solar photovoltaics (PV) are the fastest growing energy source globally because of its environmental and economic benefits. Solar generating capacity has grown nearly 2500% globally since 2000, and it is estimated that worldwide capacity will be 774 GW by the end of 2020. During the past 5 years, solar has expanded to more than a third of all new power generating capacity in the US.

Global Solar PV Installed Capacity

2000-2020

Source: Our World in Data, Global Change Data

Building Solar: A Look at the Supply Chain

Solar PV manufacturing is a global industry that began its ascent in the United States, European Union, and Japan in the 1970s. During the past two decades, China has solidified itself as a leading PV module manufacturer, with the solar PV supply chain now spanning the globe. As it has grown, the solar PV supply chain has become fully commoditized, which has been a contributing factor to driving down the price of solar by 70% during the last 10 years.

What is the Supply Chain?

Crystalline Silicon PV Supply Chain

Polysilicon

It starts with polysilicon – the same material in computer chips.

Ingot/Wafer

Polysilicon is then turned into cylindrical ingots which are sliced into wafers.

Cell

Wafers are turned into PV cells – the heart of a solar panel.

Module

Cells are assembled into a traditional PV module with a metal frame and glass cover. Thin film PV involves coating a flexible plastic sheet with photovoltaic materials.

System

Panels are installed in the field in large frames and placed on a racking or tracker system. They are then connected to electronic devices (inverters) that convert the direct current produced by the panels into the alternating current fed into the power grid.

Thin Film PV Supply Chain

Glass

Semi-conductor Deposition

Cell Definition

Module

"Embodied" Carbon in the Solar Supply Chain

While solar energy produces no emissions in its operations and typically offsets greenhouse gas (GHG) and other emissions from fossil-based electricity generation, there is more to cutting carbon than one might think. The GHG emissions associated with how things are produced and transported have an appreciable impact on the embodied carbon (solar supply chain emissions) footprint of any given product. Though solar PV is a key clean energy technology, there are still GHG emissions to consider when it is made.

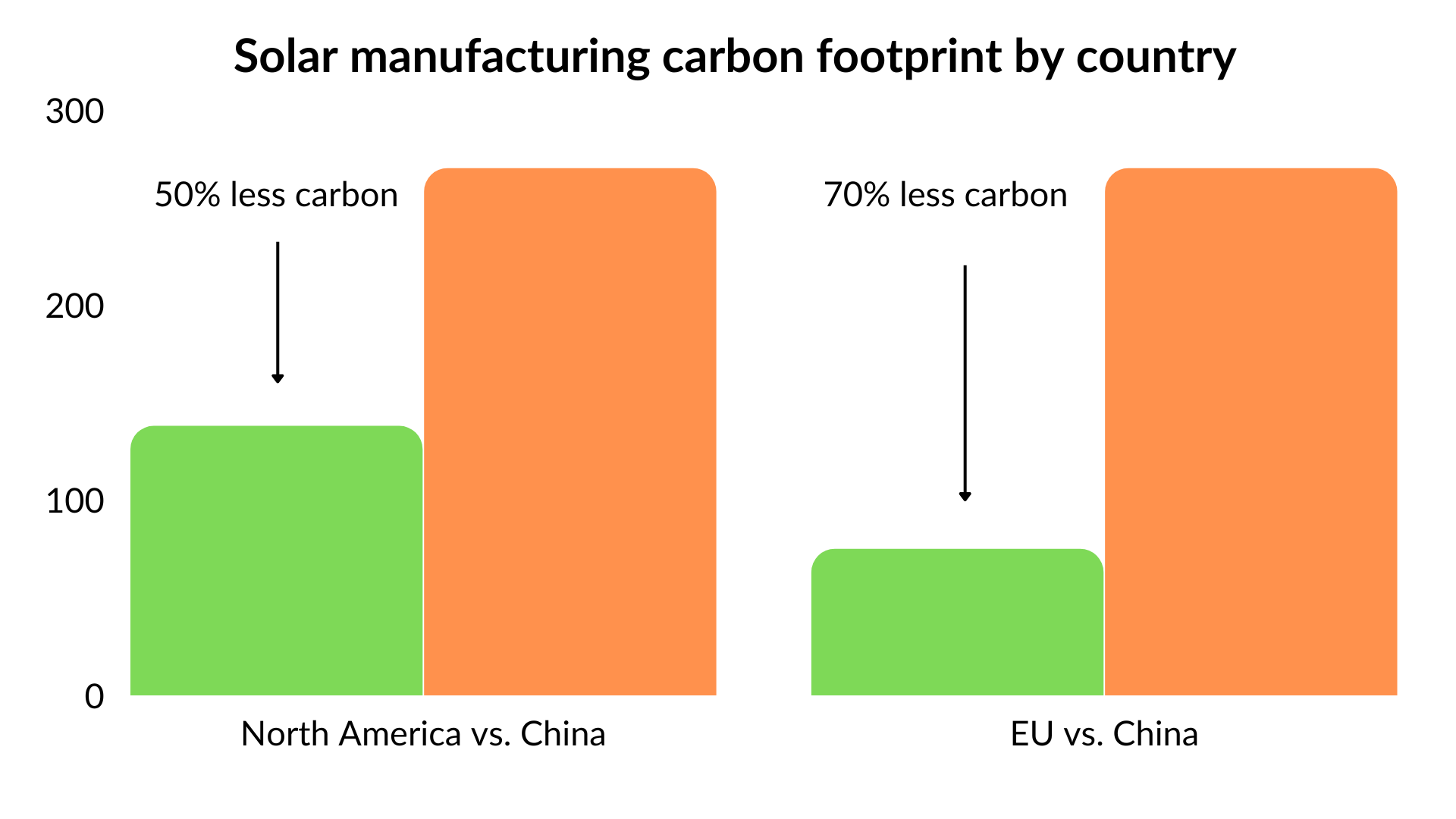

Studies have shown that how solar PV is produced can have as much as a 50% impact on the total embodied carbon of a solar panel. Why is this? Because major components in solar PV technology such as polysilicon require energy intensive processes to mine the raw materials and purify them into solar grade polysilicon.

The Path to Ultra Low-Carbon Solar

Solar PV is the fastest growing energy source in the world in part because of its environmental benefits as compared to fossil fuels. But there is an opportunity to make solar PV even more environmentally beneficial than it already is.

By sourcing PV panels incorporating key inputs like polysilicon made with smaller carbon footprints, solar projects can reduce embodied supply chain emissions by 50%.

Multiple companies that produce low carbon polysilicon and thin film technologies for solar modules are already decarbonizing their operations. These enable solar PV with significantly lower embodied carbon that typical PV. These better solar products are already in the market today. By choosing ultra low-carbon solar, Fortune 500 companies and governments alike can cost-effectively achieve additional carbon reductions when they deploy PV.

How Much Better is Ultra Low-Carbon Solar vs. Typical Solar?

At the Global Level

(10 Years of Projected Solar PV Deployment)

Can avoid 2 Billion Metric Tons of Supply Chain Emissions

At the Global Level

Equal to Conserving 225 Billion Gallons of Gasoline.

Sources: Yue, You, Darling, Domestic and overseas manufacturing scenarios of silicon-based photovoltaics: Life cycle energy and environmental comparative analysis.

Emissions values calculated with the EPA's Greenhouse Gas Equivalencies Calculator

Technical Studies & Other Resources

- 1Solar PV Global Supply Chains

- 2Catalyzing American Solar Manufacturing

- 3Solar Photovoltaics Supply Chain Review Report.

- 4Embodied energy and carbon from the manufacture of cadmium telluride and silicon photovoltaics.

- 5Decarbonizing Industrial Supply Chain Energy (DISC-e)

- 6Global Energy Transition Outlook 2022

- 7Solar Photovoltaic (PV) Manufacturing Expansions in the United States, 2017–2019: Motives, Challenges, Opportunities, and Policy Context

- 8Solar Futures Study

- 9Expanding the Photovoltaic Supply Chain in the United States: Opportunities and Challenges

- 10EU Manufacturing Map

- 11Differences in CO2 emissions of solar PV production among technologies and regions: Application to China, EU and USA (abstract)

- 12PV Sustainability Activities - Task 12 Reports

- 13The Energy and Environmental Performance of Ground-Mounted Photovoltaic Systems—A Timely Update

- 14Life Cycle Assessment Harmonization - Solar Photovoltaics

- 15Domestic and overseas manufacturing scenarios of silicon-based photovoltaics: Life cycle energy and environmental comparative analysis (abstract)

- 16Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies

- 17Life Cycle Greenhouse Gas Emissions of Crystalline Silicon Photovoltaic Electricity Generation Systematic Review and Harmonization