South Korea recently announced that the country is implementing a Carbon Footprint Assessment standard for the solar modules employed under its Renewable Portfolio Standard (RPS) and other public projects. The new policy will mean that solar manufacturers will need to verify their carbon footprint across the manufacturing supply chain, and that carbon footprint is factored into project bid evaluations. This is similar to France’s Lifetime Carbon Assessment system to help reduce greenhouse gas emissions in the solar supply chain.

Increasingly, governments and corporate buyers are becoming aware of the embodied carbon concerns associated with some solar manufacturing. As global demand for solar surges we need to make sure solar manufacturing emissions do not follow suit. Ultra Low-Carbon Solar is the straightforward and available solution to avoid unnecessary embodied carbon in solar manufacturing.

As France and South Korea stake out leadership positions in decarbonizing solar energy, other nations and corporations have the opportunity to join them at the table by making clear public commitments to reducing embodied carbon in the solar they deploy. Solar buyers can send a clear market signal by committing to Ultra Low-Carbon Solar. Multiple module companies are producing ULCS modules today, and increased demand will signal the market to more broadly shift to lower carbon solar manufacturing.

You can learn more about the changes South Korea is making by reading the pamphlet below, provided to us by our friends at PINK Strategy.

South Korea is implementing Carbon Footprint Assessment regulation for Photovoltaic energy market

A large and fast-growing market

With a target set by its Renewable Energy 3020 Implementation Plan at 20% of energy from renewables by 2030, South Korean PV market exceeded 3GW in 2019 and has been rapidly growing over the last years (over 30% annual growth). The Ministry of trade, industry and energy of Korea released a basic plan for electricity supply and demand that sees the country installing 58.5 GW of renewables capacity by 2030, including up to 30 GW of solar.

Korean Government has not yet published the capacity of public tender for the next years, the information given is for tenders until the end of 2020. We will keep you updated in the following news.

Implementation of an incentive for low carbon photovoltaics

South Korea (Ministry of Trade, Industry and Energy) has developed a CFP system for solar modules to strengthen the competitiveness of the renewable energy industry in the country. This system will quantify and verify the total amount of greenhouse gases per unit output (1 kWc) emitted by the entire process of manufacturing solar modules (Polysilicon/ingot/wafer/cell/module/frame), for products manufactured by domestic and foreign photovoltaic module manufacturers.

The ministry’s objective is to contribute to global greenhouse gas reduction but also further strengthen the competitiveness of the domestic solar energy industry. This system will be applied to the Renewable Portfolio Standard (RPS)1 and public projects.

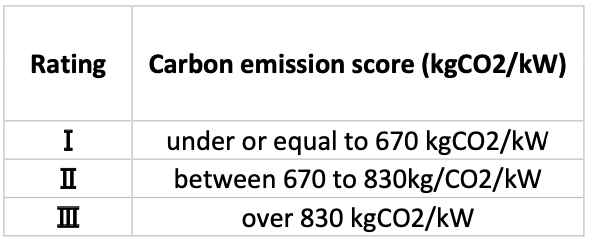

Calculation of the CPF for solar modules will be used to classify modules into three grades, depending on the carbon emission. The score will be directly linked to incentives in the RPS selection bidding market, and government projects (to be implemented in the near future). Please see details in the table below:

1 RPS programme requires 13 largest power companies (with installed power capacity larger than 500 MW) to steadily increase their renewable energy mix in total power generation in period of 2012-2024. Source: IEA/IRENA Renewables Policies Database

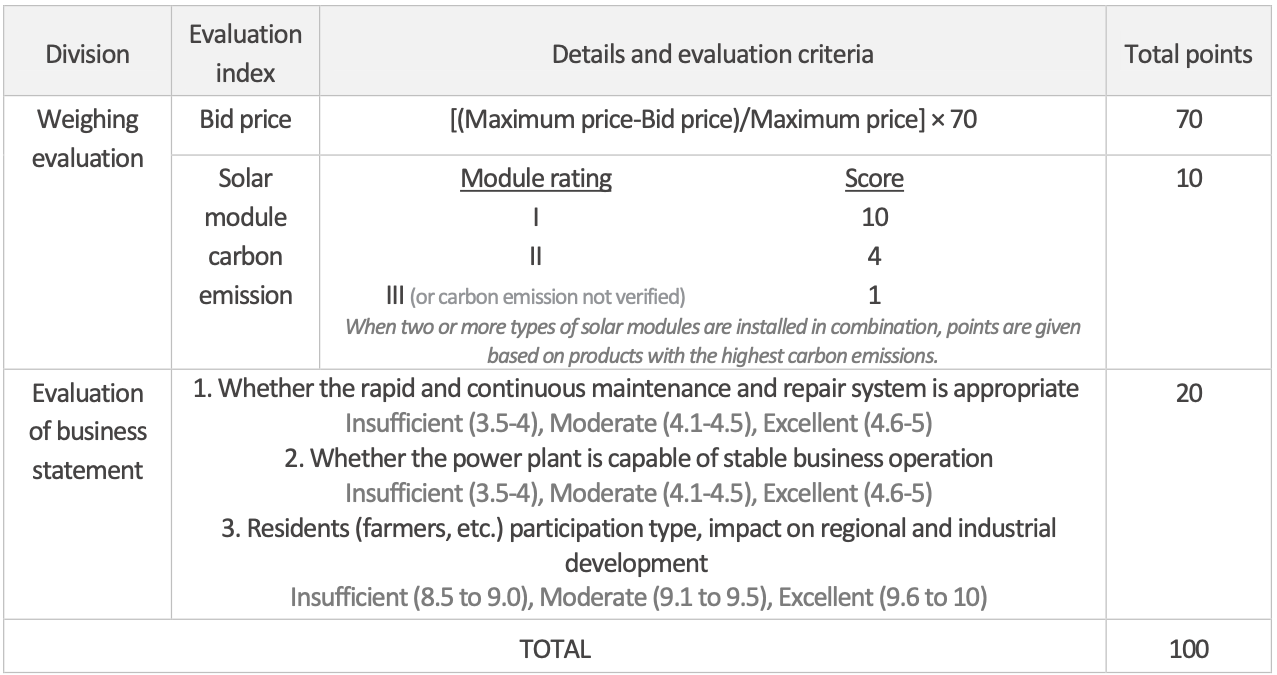

The CFP represents 10% of the total note on the selection and evaluation criteria for public and RPS calls for tenders for a fixed price contract. (70% is linked to the price offer and 20% for the commercial offer). Please check the table below for more details:

How the CFP is calculated?

This regulation, largely inspired by the French Public tender regulation, requires for module manufacturer to submit an application to the government for verification and approval of the calculated carbon footprint emission. This calculation can be done by two methods: Method by Standard Emission Factor or Methods by Life Cycle Assessment (LCA).

Evaluation by Standard Emission Factor of PV modules

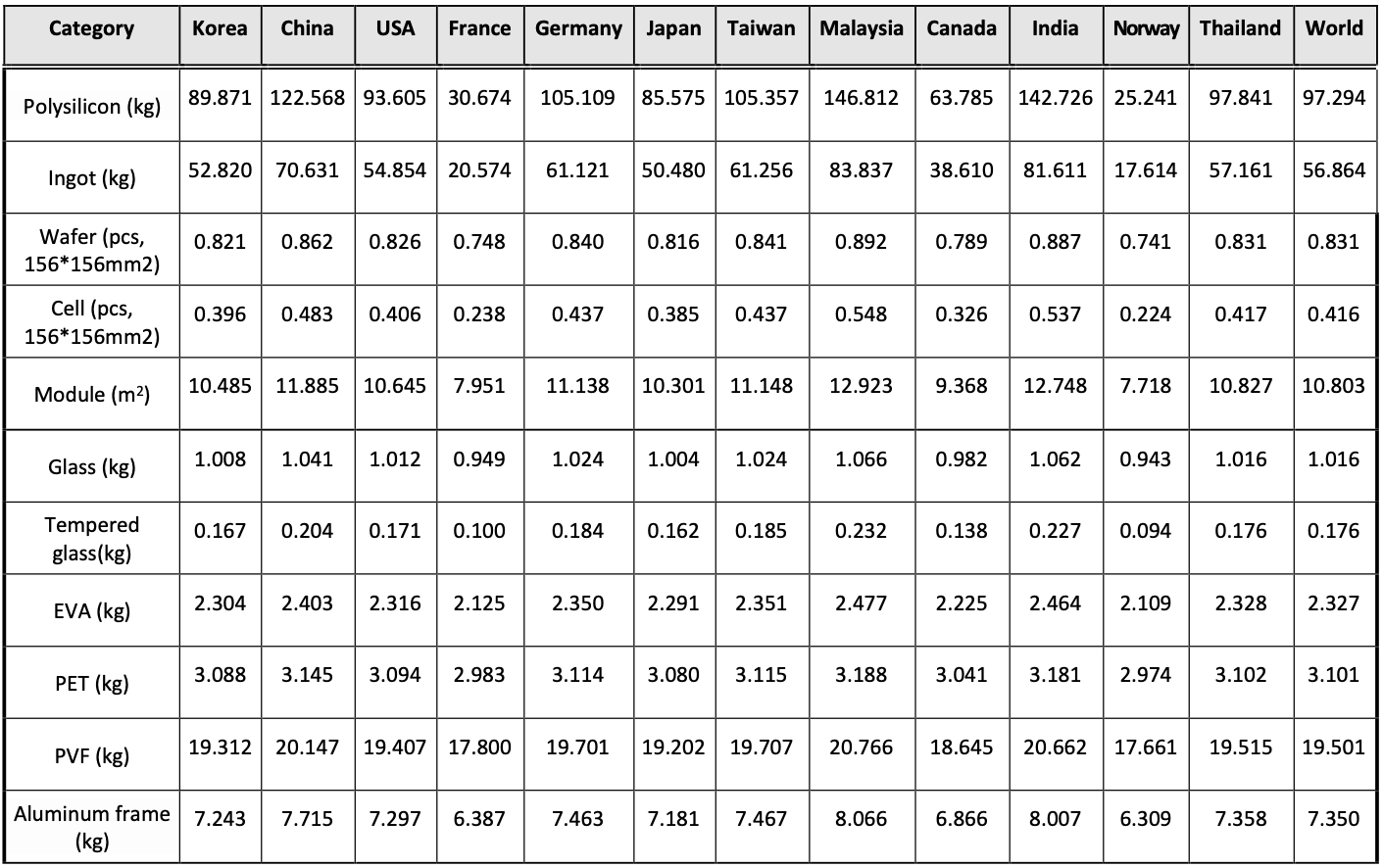

Korean CFP default calculation is based, on official default values per component and country (as per French Tenders) without breakages and losses (as per French Methodology CRE3).

Evaluation of score by LCAs

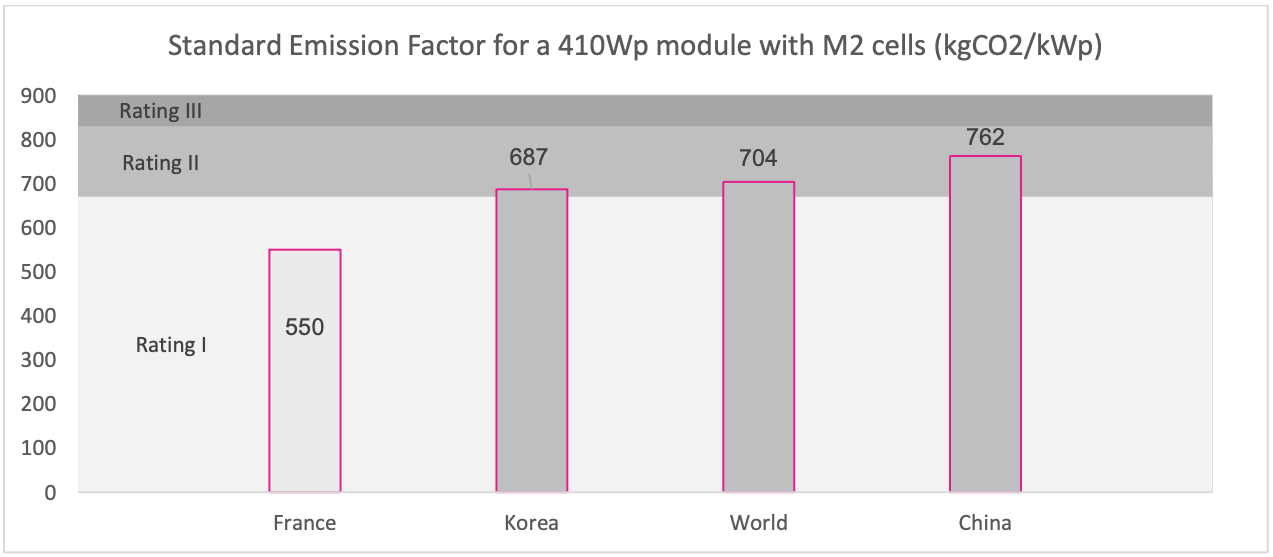

Default score may be improved by issuing LCAs in production factories. Validation and submittal processes are necessary to be able to use the results calculated by the LCA. The calculations should be based on ISO 14040 and the energy mixes given by the agency and shown in the graph below:

LCA Submittal process

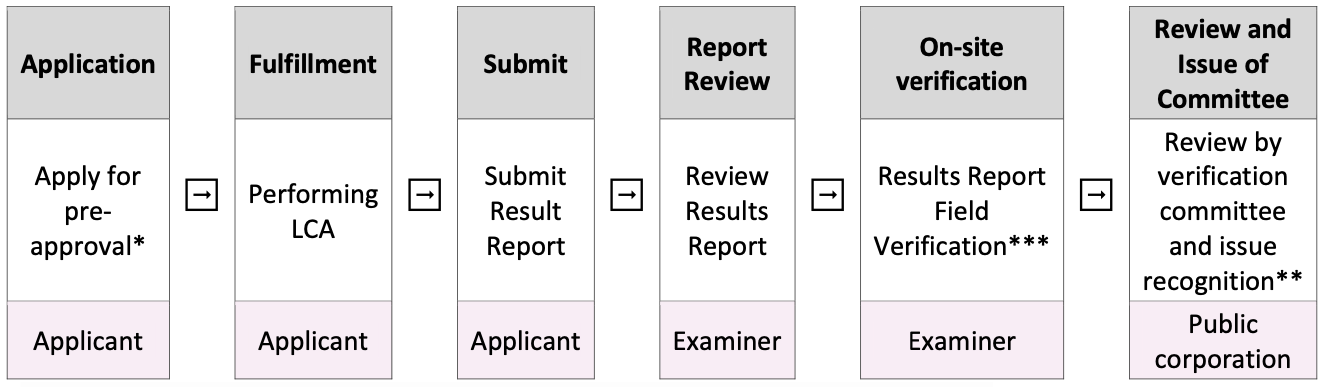

The applicant (a module manufacturer, for example), needs to ask for a pre-approval from the authorities to be able to send the LCA for validation by Korean Government. The LCA needs to be performed by a consulting company with at least three years of experience with LCA performing and based on methodology ISO 14040. The government will review the study, audit the data and the factory*** and if all is compliant will issue recognition that will be valid to be used in the Korean market for one year.

* LCA can be carried out after the approval of the Corporation for LCA pre-approval.

** Issue of recognition if the results of the review by the verification review committee are appropriate.

*** Regarding the present sanitary situation, the onsite audit has been exempted.

Standard Emission Factor of PV modules verification process

An application has to be submitted to the Korean government (Ministry of Trade, industry and Energy) for verification. It may be audited to attest the veracity of information provided. The application must contain:

- A list of components necessary to manufacture photovoltaic modules including the quantity of each component required to manufacture a unit module (BOM, official documents, specifications, etc.);

- The calculation result, that needs to be done using the calculation tool provided by the Korean government;

- Corporate documents from the company applying for the certification;

- Verification Fees.

The government can schedule an on-site visit on the manufacturing site to verify the information provided (fees may apply).

Once all data provided and verified, the certification has a validity of three years and can be renewed.

Life Cycle Assessments (LCA) already performed by PINK can be used in the scope of Korean market with minimal update. PINK has performed several LCAs and Environmental product declarations that can be used for the Korean Market. Do not hesitate to contact us for more information.

Dare PINK, Go Green!