The Ultra Low-Carbon Solar Alliance is excited to announce the launch of our Guest Authors Series for the Alliance blog! With so many innovative leaders helping drive sustainability in the solar sector, we wanted to expand the array of experts the Alliance draws on for perspectives about global solar supply chain decarbonization. We’re honored to have Cecilia Bergman of PINK Strategy, a leading EU firm with ten years of experience in solar projects, carbon performance consulting and innovative projects in electrical mobility, kick off this series with a piece about the French Government’s program requiring public procurement of solar with low embodied carbon.

Reducing the Carbon Footprint of Solar: the French Model

By Cecilia Bergman

The French PV market is the fourth largest in Europe with 1GW installed each year. France has an objective to have a total of 20.6 GWp of solar installed by 2023, consistent with EU energy policies. As part of the European Green Deal, the Commission proposed in September 2020 to raise the 2030 greenhouse gas emission reduction target, including emissions and removals, to at least 55% compared to 1990. The key targets for 2030: are to have at least 40% cuts in greenhouse gas emissions (from 1990 levels); at least 32% share for renewable energy and at least 32.5% improvement in energy efficiency. To meet this target from renewable energies perspectives, connections to the grid will have to increase to around 3 GW per year. Tenders for solar projects on the public grid are organized by the “Commission de Régulation de l’Energie” (French Energy Regulation Council, “CRE”), and a guarantee of 20-year fixed price for electricity generated from these projects gets the attention of the biggest project developers and modules manufacturers in the world.

What differentiates the market in France from its European neighbors is what we call a simplified carbon assessment (ECS – Evaluation carbone simplifiée). Currently obligatory for projects over 100kWp, this certification requires that modules being installed in projects in France have passed through a specific calculation that certifies the life cycle carbon impacts associated with each step of the PV module’s manufacturing and assembly. France sets a maximum embodied carbon footprint for PV modules depending on the size of the project, and the carbon footprint can represent up to 30% of the final score on grading a company’s tender application. Since 2011, most large PV module manufacturers have made the effort to improve the carbon footprint of sufficient modules in order to be competitive in this market. This has required most Tier 1 suppliers along the solar supply chain to perform standardized Life Cycle Assessments of their manufacturing process to determine embodied carbon content. It is by largely by using solar cells produced with lower embodied carbon polysilicon and wafers that module makers have met the carbon footprint targets.

How is this ECS (embodied carbon) calculated?

There are two methods to calculate the ECS final score:

- The first relies on tables of default carbon footprint values for each step of the supply chain by country of manufacture. This does not require company-specific life cycle assessments (LCA) instead, this approach uses standard values from CRE data or the relevant literature and is very conservative, producing higher carbon footprint values than the company-specific LCA approach.

- The second method involves the completion of full life cycle assessments (following global LCA standards) along the solar supply chain:

- These LCAs produce embodied carbon values based on company-specific manufacturing processes at each step of the supply chain.

- This more detailed method uses manufacturer’s actual operations data rather than conservative defaults and generally produces lower embodied carbon levels than the look up table method.

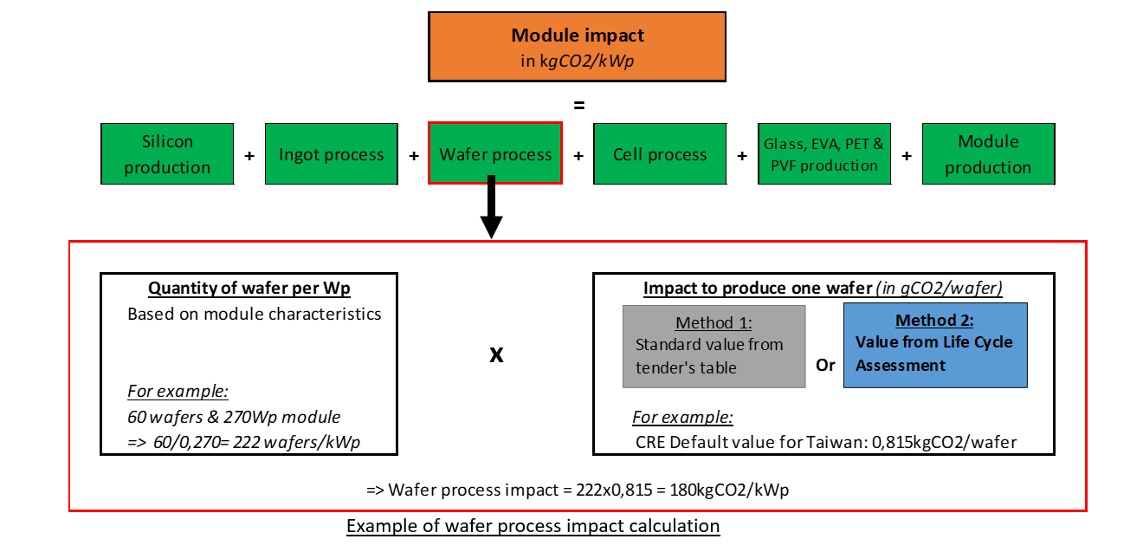

In both cases the values derived for each step of the supply chain are summed up to represent the total embodied carbon of the finished solar module. The final ECS calculation is represented below. The impact of the module production is the sum of all steps in the module manufacturing and the module assembly:

How can the carbon footprint be optimized?

Life cycle assessments are a great tool to assess the real impact of one manufacturing process (from silicon manufacturing to module assembly) and identify potential opportunities for optimization. When a manufacturing process is optimized (e.g., better energy sources, low energy consumption, state of the art machinery, low consumption of materials, etc.), its kgCO2-eq per functional unit is improved, resulting in a lower GWPij (Global Warming Potential) score that will be used in the ECS. This more detailed method has been chosen with more and more frequency by manufacturers that want to enter the French public PV market.

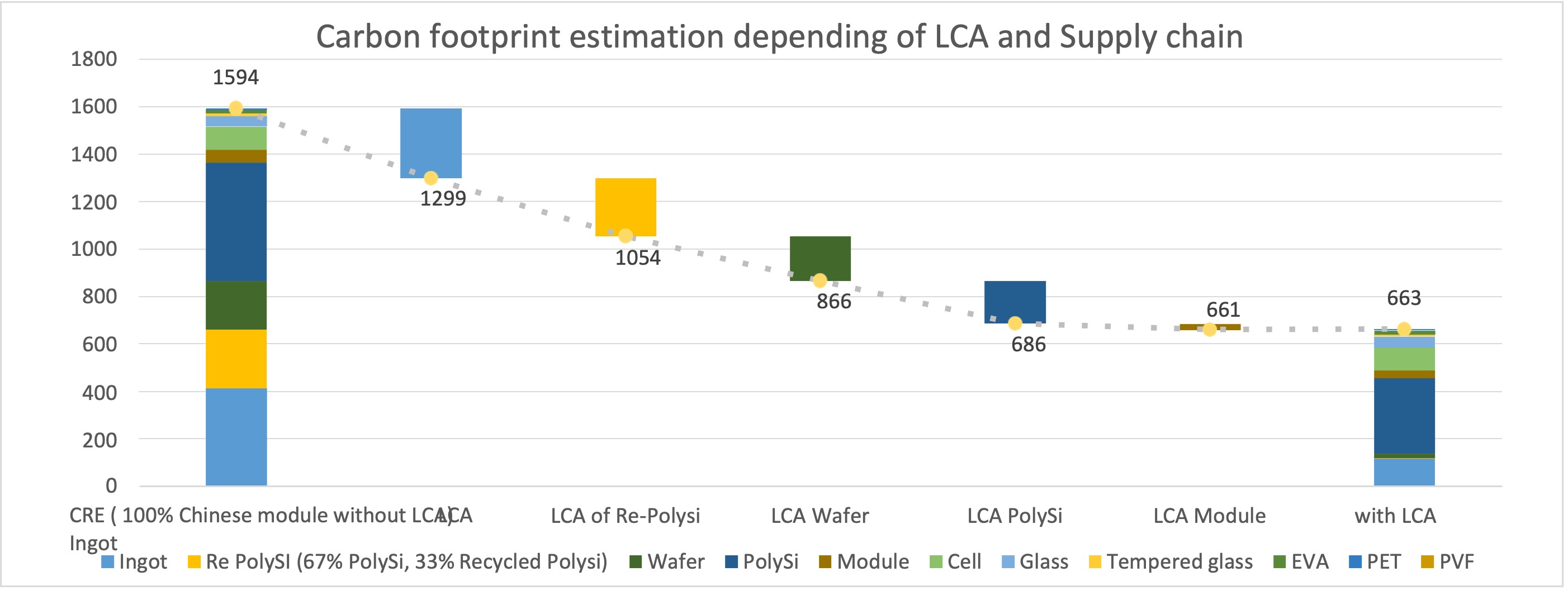

An example of a supply chain based on LCA compared with a supply chain based in default values can be seen below:

This demand for low embodied carbon modules in the CRE program has clarified the need for an optimized low carbon solar supply chain, and has obliged the main stakeholders to invest in carbon optimization to be competitive in the French market. The French example has inspired other countries worldwide: several have been showing interest in the methodology and South Korea has implemented a similar methodology for its home market in 2021.

---

About Solstyce/PINK

A subsidiary of SOLSTYCE, PINK STRATEGY, created in 2020, relies on 10 years’ experience in Carbon performance Consulting developed by Solstyce.

PINK Strategy is an integrated consulting company specializing in environmental performance and asset life cycle management. A leader on the photovoltaic market, PINK Strategy has been supporting the main manufacturers of photovoltaic panels for 10 years in their low carbon initiatives. PINK Strategy supports manufacturers and construction players in optimizing their energy consumption and return on carbon investment and distinguishes itself through an integral approach to the life cycle of equipment and installations, combining economic and ecological performance.